Zimbabve va Sudan uchun 1400 1500 1600 oltin ho'l pan tegirmon Chili tegirmoni

Oltin ho'l pan tegirmon mashinasi turli quvvatlarga ega bo'lgan turli modellarga ega. Kichik model 1100 va 1200 modeli bo'lib, odatda Sudan, Misr, Mavritaniya va Nigerda qo'llaniladi. Katta sig'imga Zimbabveda mashhur bo'lgan 1400,1500 va 1600 modellari kiradi. Va katta ho'l pan tegirmon mashinasi odatda jag' maydalagich, oltin kontsentrator yoki oltin kacha kontsentratori bilan birga ishlatiladi. Katta ho'l pan tegirmonning quvvati 1100 va 1200 modelga qaraganda ancha yuqori, masalan, 1500 ho'l pan tegirmon mashinasi soatiga deyarli 2 tonnaga yetishi mumkin.

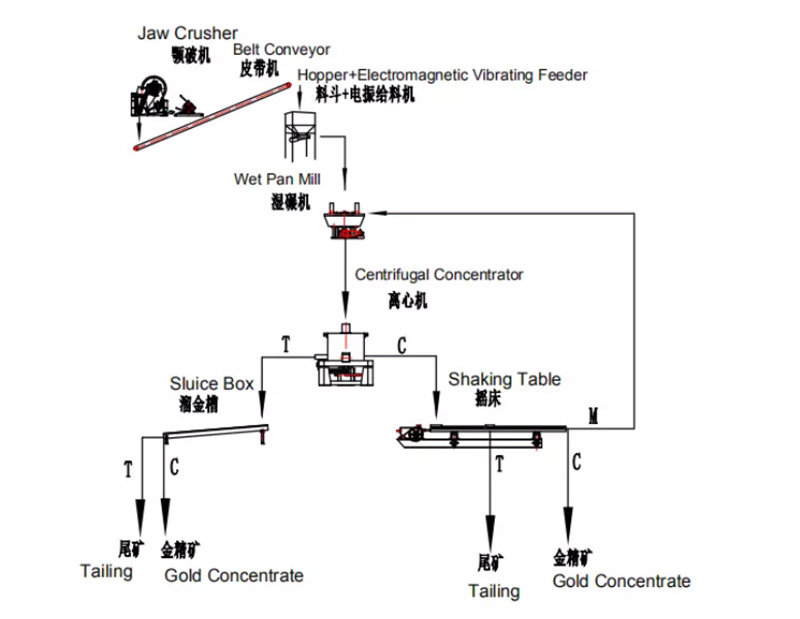

Nam pan tegirmon oltin qazib olish yechimi

Tosh jag' maydalagichga solinadi va tosh 20 mm dan kam bo'lmagan mayda zarrachalarga eziladi. Keyin tosh zarralari oltin ho'l pan tegirmon mashinasiga uzatiladi. Ho'l pan tegirmonidan olingan atala oltin boyitish fabrikasiga o'tkaziladi, unda oltin konsentratining bir qismi boyitish fabrikasining yivlarida saqlanadi. Kontsentratsiyadan olingan qoldiq silkituvchi stolga tushadi va qolgan oltinning bir qismini oltin silkituvchi stol yordamida qayta tiklash mumkin.

Nam pan tegirmonining texnik xususiyatlari

| Model | Texnik xususiyatlari | Kirish hajmi | Aylanish tezligi | Imkoniyat | Quvvat | Mashinaning og'irligi |

| 1600A | 1600×400/2100×500*180±20mm | <30 mm | 18-20 | 5-6T/soat | 37 kVt | 16.3 |

| 1500A | 1500×400/2100×500*180±20mm | <30 mm | 18-22 | 4-5T/soat | 30 kVt | 13.5 |

| 1500B | 1500×350/2050×450*150±20mm | <30 mm | 18-22 | 4-5T/soat | 22 kVt | 12.3 |

| 1500C | 1500×300/2050×400*150±20mm | <30 mm | 18-22 | 4-4,5T/soat | 22 kVt | 11.3 |

| 1400B | 1400×250/2050×350*150±20mm | <30 mm | 18-22 | 3-4T/soat | 15 kVt | 8.5 |

| 1400A | 1400×300/2050×400×150±20mm | <30 mm | 18-21 | 3-4T/soat | 18,5 kVt | 9.6 |

| 1300B | 1300×250/2000×350×150±20mm | <30 mm | 18-22 | 2,5-3,5 T/soat | 11kVt | 7.5 |

| 900A | 900×170/1700×220×45±10mm | <30 mm | 11-13 | 0,1-0,5T/soat | 3kVt | 2.9 |

| 900B | 900×140/1700×170×45±10mm | <30 mm | 11-13 | 0,1-0,5T/soat | 3kVt | 2.6 |

| 1200A | 1200×200/1800×250×100±10mm | <30 mm | 11-19 | 2-3T/soat | 7,5 kVt | 5.5 |

| 1200B | 1200×180/1800×250×100±10mm | <30 mm | 11-19 | 2-3T/soat | 5,5 kVt | 5.5 |

| 1100A | 1100×200/1800×250×100±10mm | <30 mm | 11-19 | 1-2T/soat | 7,5 kVt | 5 |

| 1100B | 1100×180/1800×250×80±10 mm | <30 mm | 11-19 | 1-2T/soat | 5,5 kVt | 5 |

| 1000 | 1000×200/1800×250×80±10mm | <30 mm | 11-19 | 0,5-1T/soat | 5,5 kVt | 4.5 |

Nam pan tegirmon yetkazib berish